| When you first buy a Rover, you tend to

tread carefully, not daring to dismantle anything more than absolutely

necessary, just in case you can't put it together again. This means that

it can take many years to find your way around a land Rover, dismantling

more with each repair job, as you become more confident - or foolhardy.

My

109" from 1976 has had several major rebuilds, but never the total stripdown

- until this year. I intended to service the front axle, and maybe give

the bodywork a lick of paint. But shipfitters disease set in, and over

a few days i discovered that I'd uncovered most of the chassis. I found

a few rust spots, and I was considering metalising the chassis anyway -

but this requires agressive sand-blasting, which i was afraid would reveal

even more rusty patches. But it seems a pity to just cover it up with paint

again, because stripping the body is half the job. I then discovered that

due to the vehicles age, i would not have to pay much - if any - registration

tax on fitting a new frame, and a new frame could be galvanised. My

109" from 1976 has had several major rebuilds, but never the total stripdown

- until this year. I intended to service the front axle, and maybe give

the bodywork a lick of paint. But shipfitters disease set in, and over

a few days i discovered that I'd uncovered most of the chassis. I found

a few rust spots, and I was considering metalising the chassis anyway -

but this requires agressive sand-blasting, which i was afraid would reveal

even more rusty patches. But it seems a pity to just cover it up with paint

again, because stripping the body is half the job. I then discovered that

due to the vehicles age, i would not have to pay much - if any - registration

tax on fitting a new frame, and a new frame could be galvanised.

Here's

the old frame - now standing up against the wall. The paint is five years

old, with no underseal - most of the rusty patches are surface rust, revealed

by my scraping and brushing. Apart from a few bad spots, it's in remarkable

condition. Here's

the old frame - now standing up against the wall. The paint is five years

old, with no underseal - most of the rusty patches are surface rust, revealed

by my scraping and brushing. Apart from a few bad spots, it's in remarkable

condition.

One of the drawbacks of being a professional

photographer, is that you don't get around to taking pictures until it's

too late. When the rebulid was almost complete, I took a tv-camera and

shot these stills.

This

is the result of three months work - a naked rover, ready for brakes, steering

and engine alignment - much easier for the workshop to do before the bodywork

gets put on. All parts, including the dashboard and engine compartment,

have been take off, stripped to bare metal, and painted with 2 coats rust

paint and 2 coats black enamel. A new firewall has been fitted. The firewall

and other steel parts have been metalised to prevent rust. I don't use

underseal, nor do I intend to paint the chassis, but I will treat the inside

of the box frame chassis with tectyl or waxoyl. This

is the result of three months work - a naked rover, ready for brakes, steering

and engine alignment - much easier for the workshop to do before the bodywork

gets put on. All parts, including the dashboard and engine compartment,

have been take off, stripped to bare metal, and painted with 2 coats rust

paint and 2 coats black enamel. A new firewall has been fitted. The firewall

and other steel parts have been metalised to prevent rust. I don't use

underseal, nor do I intend to paint the chassis, but I will treat the inside

of the box frame chassis with tectyl or waxoyl.

This

is how I like to see a Land Rover! Of course they get dirty, but a regular

wash with a high pressure jet helps. Maintaining a vehicle underneath is

much easier - and cleaner work - if you don't have to fight underseal.

Underseal is great on a new vehicle - for the first owner! But it can hide

a multitude of sins - rust can develop behind it, and it's difficult to

see until it's developed as a real problem. Underseal is also a problem

if you have to weld, because it burns easily. I usually paint the chassis,

but as its galvanised, it is not necessary - or so my Land Rover collegues

on the internet tell me from their experience. The next few years will

tell... This

is how I like to see a Land Rover! Of course they get dirty, but a regular

wash with a high pressure jet helps. Maintaining a vehicle underneath is

much easier - and cleaner work - if you don't have to fight underseal.

Underseal is great on a new vehicle - for the first owner! But it can hide

a multitude of sins - rust can develop behind it, and it's difficult to

see until it's developed as a real problem. Underseal is also a problem

if you have to weld, because it burns easily. I usually paint the chassis,

but as its galvanised, it is not necessary - or so my Land Rover collegues

on the internet tell me from their experience. The next few years will

tell...

Besides

the motor and gearbox, rebuilding the front axle is probably the most complicated

and time consuming job on a Series Land Rover. All bearings, oil seals

and gaskets have been replaced, and leather gaiters have been fitted over

the new swivel balls. All brake components have been replaced too. The

steering tracking rods have been metallised to prevent rust. It is important

to fit tie rod ends with grease nipples so that they may be lubricated.

The axial tracking rod inside the motor compartment, between the drop arm

of the steering bos and the steering relay in the front cross member, does

not have enough space to allow for grease nipples in the tie rod ends,

as these would foul the bodypanels. There is much discussion between Land

Rover enthusiasts as to whether one should use oil or grease in the swivel

balls. I use oil. Besides

the motor and gearbox, rebuilding the front axle is probably the most complicated

and time consuming job on a Series Land Rover. All bearings, oil seals

and gaskets have been replaced, and leather gaiters have been fitted over

the new swivel balls. All brake components have been replaced too. The

steering tracking rods have been metallised to prevent rust. It is important

to fit tie rod ends with grease nipples so that they may be lubricated.

The axial tracking rod inside the motor compartment, between the drop arm

of the steering bos and the steering relay in the front cross member, does

not have enough space to allow for grease nipples in the tie rod ends,

as these would foul the bodypanels. There is much discussion between Land

Rover enthusiasts as to whether one should use oil or grease in the swivel

balls. I use oil.

The

motor block was rebored and fitted with new pistons, valves, camshaft,

bearings and timing chain five years ago and is still in excellent running

order. On this rebuild I removed all external parts and each has been cleaned,

services, painted and reassembled. The motor block is painted with "John

Deere" tractor paint - bright green, which holds its colour and coating

well even on a hot motor. A clean and painted motor makes tracing oil leaks

easy work, and can be washed with soapy water. I have fitted a new 160A

Varta battery - my ideal choice for a battery which can start a diesel

in the cold winter months in Denmark. Here are some other shots of the

engine and front end of the vehicle. The

motor block was rebored and fitted with new pistons, valves, camshaft,

bearings and timing chain five years ago and is still in excellent running

order. On this rebuild I removed all external parts and each has been cleaned,

services, painted and reassembled. The motor block is painted with "John

Deere" tractor paint - bright green, which holds its colour and coating

well even on a hot motor. A clean and painted motor makes tracing oil leaks

easy work, and can be washed with soapy water. I have fitted a new 160A

Varta battery - my ideal choice for a battery which can start a diesel

in the cold winter months in Denmark. Here are some other shots of the

engine and front end of the vehicle.

In my experience, most faults on a Land

Rover are due to age - because the chassis, motor and drive chain last

so long, the vehicle becomes old enough for things which never fail on

other cars to wear out - loose fittings, loose electrical connections,

rusty joints - all of which get cured in a rebuild simply by being cleaned,

rebuilt or replaced. It is easy to strip a Land Rover, but important to

dissemble every part - the heater system and air vents being a typical

example. Clean them, rebuild them, and they will work like new for many

years.

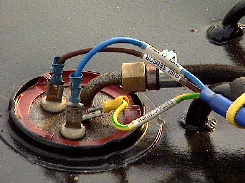

I

have undertaken an number of modifcations, including fitting a master switch

between the 12 volt positive terminal of the battery and the starter motor.

This switch has a removeable key - besides being a useful anti-theft device,

it makes it easy to cut off all power on the vehicle in the event of electrical

failure or maintenance. This switch is mounted on the motor side of the

passenger side firewall. The wiring loom has been totally rebuilt using

original colour codes - except for the lines to the rear end, which have

been replaced with 7 core 1.5mm2 trailer cable. All cable ends have been

labelled with small printed labels which are covered with transparent heat

shrink sleeving. This makes future dismantling and fauilt tracing very

easy - especially on the rear lights and trailer socket which have to be

disconnected when the rear tub is removed. I

have undertaken an number of modifcations, including fitting a master switch

between the 12 volt positive terminal of the battery and the starter motor.

This switch has a removeable key - besides being a useful anti-theft device,

it makes it easy to cut off all power on the vehicle in the event of electrical

failure or maintenance. This switch is mounted on the motor side of the

passenger side firewall. The wiring loom has been totally rebuilt using

original colour codes - except for the lines to the rear end, which have

been replaced with 7 core 1.5mm2 trailer cable. All cable ends have been

labelled with small printed labels which are covered with transparent heat

shrink sleeving. This makes future dismantling and fauilt tracing very

easy - especially on the rear lights and trailer socket which have to be

disconnected when the rear tub is removed.

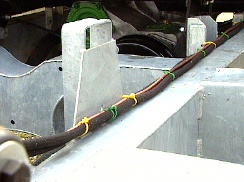

Working

on the brakes and steering is much easier when the body is removed, but

it is important to be able to sit in the driving seat. During a rebuild

it can be difficult to move the vehicle if there is no seat, and as the

seat console is supported by the rear tub, which is removed for painting,

I decided to build some temporary support brackets which can support the

seat console and drivers seat back. These will also fit my 88" chassis,

so they will come in handy. Working

on the brakes and steering is much easier when the body is removed, but

it is important to be able to sit in the driving seat. During a rebuild

it can be difficult to move the vehicle if there is no seat, and as the

seat console is supported by the rear tub, which is removed for painting,

I decided to build some temporary support brackets which can support the

seat console and drivers seat back. These will also fit my 88" chassis,

so they will come in handy.

Here are some other views of the finished

rolling frame -

Practice makes perfect! I have had a lot

of practice, but I am far from perfect yet. I have mastered the art of

taking apart and rebuilding the mechanical parts, but the final finish

- especially painting the bodywork, is something which I am still working

hard to master. It gets easier with every rebuild. I have given up painting

the car as a finished unit - too much paint gets onto other parts, and

nooks and crannies, where rust or corrosion will later appear, do not get

coated by a cosmetic job. Each part is cleaned, sanded, washed, primed

with rust paint 8yes even the aluminium - red oxide is a much better primer

than the expensive primers, and it helps prevent galvanic corrosion too.

The on with the topcoat - British Leyland Motor Company colour 6412 Land

Rover light green, a single cover paint which is thinned with Xylene thinners

- you can spray on all you like until about an hour after the last coat

- then you must wait 6 weeks for the paint to cure before adding more,

it may just bubble. Plently of fresh air and daylight is the order of the

day, and breathing apparatus, safety clothing is essential. Do not try

to use auto paint unless you have studied the safety aspects, this stuff

is potent to work with. Here's some shots of the body parts drying.

Of course the most satisfying process -

that which has kept me going for four months, is putting the vehcile back

together and seeing the finished result. In the space of a couple of days,

a workshop which resembles a battle-field becomes curiously empty, as all

the parts become a whole - leaving behind a pile of dirty tools, discarded

parts (many of which will be rebuilt and used on a future project) and

the usual bucket or two of rusty bolts and nuts. As a matter of principle,

I replace all nuts, bolts and washers every time I rebuild - with the exception

of special bolts on the engine for example. It makes for easy servicing

in the future, and the next rebuild in who knows how many years will go

smoother. All exposed bolt ends get a dab of silicone to prevent them getting

fould by crud and mud. I have gradually disposed of all non-standard fittings,

the entire vehicle is UNF unless the design dicates otherwise.

I use my Rovers for towing quite regularly,

often on borrowed trailers, so I have fitted the Dixon Bate adjustable

height tow hitch to all my series trucks. This allows a wide range of height

adjustment, plus the advantage that the hitch plate and hitch may be swapped

quickly for another type.

Here's some shots of the finished vehicle

-

This restoration has taken four months,

mostly evenings and weekends, and lots of nights. I don't pretend that

this is a totally original rebuild - many parts are new or aftermarket,

many small modifications to originality have been made, to suit the vehicle

to the needs of my work and my temperament. I have cut a few corners, but

the end result is a restoration which has brought new life to a trusted

friend which was already 22 years old. Barring accidents, I don't expect

to have to undertake major work on this Land Rover for many years. But

before embarking on a similar project yourself, be sure that it is what

you want - you get a nice shiny vehicle, but it's still a 1976 Rover with

the technology and quirks of vehicles of that vintage. It is still noisy,

and the 2.25 litre engine is more of a workhorse than a speed machine.

I like it that way, so I am not disappointed!

Restoration projects need a network of

human contacts who can help with parts, specialised service and advice.

As a starting pointI'd recommend subscribing to the Land

Rover Team Net on the internet - here you will meet people who have

done just the same with their trucks, and the chances are, that when you

run into problems, you will find someone who knows the answer pretty quick.

And they are a friendly bunch too!

Happy rovering!

Adrian Redmond

Channel 6 Television Denmark

e-mail landrover@channel6.dk |